In a world buzzing with wireless signals, understanding how frequency blocking materials work — and how their effectiveness is measured — is more important than ever. Whether you’re researching EMF-blocking fabrics for your bedroom or RF-shielding paint for your home office, the same scientific principles determine how well these materials block or attenuate electromagnetic energy.

This guide explains, in plain language, how experts measure the performance of frequency blocking materials, what those numbers (like “40 dB attenuation”) actually mean, and how you can use them to make informed buying decisions.

What Does “Effectiveness” Mean in Frequency Blocking?

When a product claims to “block 99% of EMF” or “reduce 5G radiation by 40 dB,” what it’s really describing is shielding effectiveness (SE) — a technical measure of how much the material reduces the strength of electromagnetic waves that pass through it.

The effectiveness of frequency blocking materials is quantified in decibels (dB), the standard unit for measuring attenuation, or signal loss.

The Basic Formula

[

\text{Shielding Effectiveness (SE)} = 20 \times \log_{10}\left(\frac{E_1}{E_2}\right)

]

Where:

- E₁ = electric field strength before the shield

- E₂ = electric field strength after the shield

In simple terms:

- 20 dB → reduces the signal by 90%

- 40 dB → reduces it by 99%

- 60 dB → reduces it by 99.9%

So, when a frequency blocking fabric or paint says “40 dB attenuation,” that means it lets only about 1% of the original energy pass through.

How Shielding Is Tested in Labs

Frequency blocking materials are tested using controlled laboratory methods that replicate real-world electromagnetic exposure. Here are the most common procedures and standards used globally.

1. IEEE 299 and ASTM D4935 Testing

- IEEE 299 (and IEEE 299.1): The gold standard for evaluating full enclosures such as Faraday cages or shielded rooms.

- ASTM D4935-18: Focuses on flat sheet materials (like fabrics or coatings). It uses a coaxial test fixture to measure how much electromagnetic energy passes through a sample across frequencies up to several gigahertz.

During these tests, engineers place a sample between two antenna systems inside a shielded environment. One side emits a known RF signal, while the other side measures how much leaks through. The difference is expressed in dB attenuation.

2. MIL-STD-285 and NSA 65-6

These U.S. military standards measure shielding effectiveness for secure rooms and enclosures. Although older, they are still used in some industrial contexts.

- MIL-STD-285: Measures RF attenuation between 100 kHz and 10 GHz using specialized test chambers.

- NSA 65-6: Applies similar methodology for TEMPEST (anti-eavesdropping) applications.

While these are military-grade protocols, some commercial manufacturers of frequency blocking materials reference them to demonstrate quality.

3. Near-Field vs. Far-Field Testing

Real-world electromagnetic fields behave differently depending on distance from the source:

- Near-field: Within about one wavelength of the source (typical of EMFs from power lines, appliances).

- Far-field: Distances beyond one wavelength (cell towers, Wi-Fi, radio).

Testing methods vary accordingly: near-field magnetic fields require different instruments than far-field RF waves. High-quality frequency blocking materials specify both.

Key Metrics Explained

Here are the most common data points you’ll see in specifications for frequency blocking materials — and what they mean in plain English.

| Metric | What It Means | Why It Matters |

|---|---|---|

| Attenuation (dB) | Signal reduction level | Higher dB = better blocking |

| Frequency Range (MHz/GHz) | Bandwidth where material was tested | Ensures protection for Wi-Fi, 5G, Bluetooth, etc. |

| Field Type | Electric, magnetic, or both | Different materials work for different field types |

| Conductivity (S/m) | Electrical conductivity of material | High conductivity = strong reflection capability |

| Permeability (μ) | Material’s magnetic field absorption ability | Relevant for low-frequency magnetic shielding |

Understanding these numbers empowers consumers to compare frequency blocking paints, fabrics, and films more intelligently.

Examples of Frequency Blocking Material Performance

Let’s look at typical values from both lab data and product specifications.

| Material Type | Example Product | Typical SE (dB) | Effective Frequency Range |

|---|---|---|---|

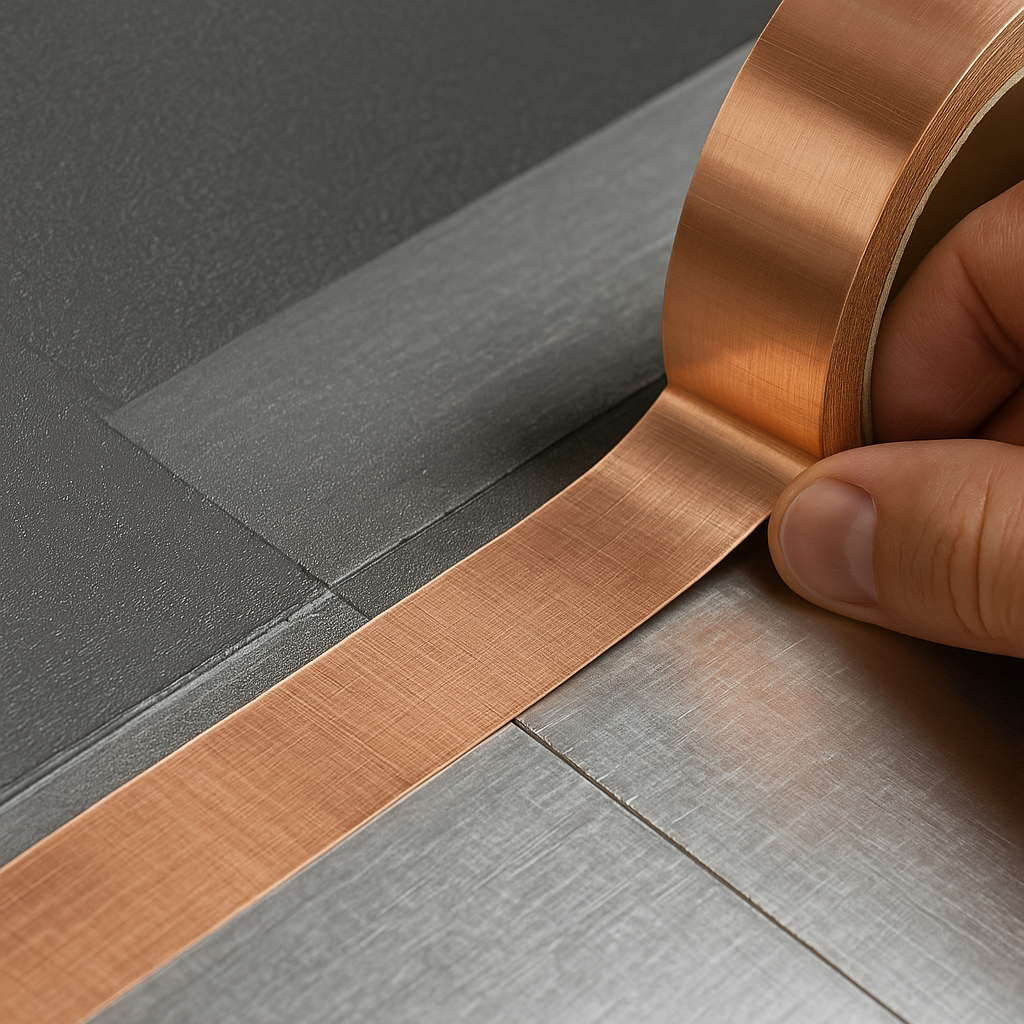

| Copper mesh / foil | Aaronia AG Copper Shielding Mesh | 60–100 dB | 100 kHz – 40 GHz |

| Silver fabric (cotton blend) | DefenderShield EMF Fabric by the Yard | 40–80 dB | 30 MHz – 18 GHz |

| Carbon-based conductive paint | WOREMOR RF-IE50 Shielding Paint | ~37–40 dB | 30 MHz – 10 GHz |

| Nickel/copper spray coating | MG Chemicals 841WB Shielding Paint | 45–55 dB | 10 MHz – 2 GHz |

| Mu-metal alloy | Amuneal Magnetic Shielding Foil | Up to 90 dB (magnetic) | Below 100 kHz |

These values show how different frequency blocking materials excel in different parts of the spectrum:

- Metals (copper, aluminum) are strong for high-frequency RF.

- Mu-metal dominates in low-frequency magnetic fields.

- Carbon paints and silver fabrics balance conductivity with aesthetics and comfort.

How Manufacturers Report Effectiveness

When browsing products online, you’ll see shielding data presented in several formats:

- Decibel Ratings (dB) — the most accurate representation of attenuation.

- Percentage Reduction Claims (“99% blocking”) — marketing shorthand derived from dB values (e.g., 20 dB ≈ 90%, 40 dB ≈ 99%).

- Laboratory Reports (PDFs) — sometimes attached as third-party verifications; credible brands like DefenderShield, SYB, and Aaronia provide these openly.

Always check whether results are independently tested or just internal estimates.

Why Lab Results Don’t Always Match Real Life

While lab testing provides standardized numbers, real-world effectiveness depends on several practical factors:

- Coverage gaps: Even tiny holes or seams can leak signal and reduce protection drastically.

- Grounding: Electric field shielding materials (like paints or meshes) must be grounded to perform correctly.

- Distance & reflection: Frequency blocking improves with distance — a phone held against your head is different from one across the room.

- Installation quality: Poorly applied coatings or unsealed seams reduce real effectiveness compared to lab data.

- Frequency overlap: Some products perform well at 2.4 GHz (Wi-Fi) but poorly at 700 MHz (cellular).

Thus, a 40 dB rating in lab conditions may translate to only 25–30 dB reduction in your home.

Testing at Home: Can Consumers Measure It?

While professional shielding tests require expensive equipment, consumers can do simple checks to gauge how frequency blocking materials perform:

1. Use an EMF or RF Meter

- Handheld meters (like Safe and Sound Pro II or Cornet ED88T) display field strength in mW/m² or V/m.

- Take baseline readings before applying the material, then measure afterward.

2. Phone Signal Test

- Place your phone in a pouch or behind shielding fabric and note signal bars or speed test results.

- This is not scientific but shows qualitative change.

3. Wi-Fi Signal Strength Apps

- Apps like “WiFi Analyzer” measure signal strength (RSSI). Compare before/after blocking material placement near routers or walls.

These tests give you a general idea of attenuation performance — just remember, they don’t replace laboratory accuracy.

How to Interpret Product Claims

Many websites use bold language like “100% protection” or “blocks 5G radiation.”

Here’s how to read between the lines:

| Claim Type | What It Likely Means | Reality Check |

|---|---|---|

| “Blocks 99% of RF” | Around 40 dB attenuation in lab | Still partial reduction, not elimination |

| “5G Shielded Fabric” | Tested up to ~40 GHz | Check for actual frequency data |

| “Anti-EMF Paint” | Conductive carbon or graphite paint | Must be grounded to work |

| “Bio-energy neutralizer” | No dB or SE data provided | Likely not a true frequency blocker |

When in doubt, look for technical data sheets (TDS) or independent test certificates. These documents often include graphs showing performance at different frequencies — a sign of a serious manufacturer.

Why Decibels (dB) Matter More Than Marketing

Decibels are logarithmic: every 10 dB increase equals a tenfold improvement in signal reduction.

- 10 dB = 90% reduction

- 20 dB = 99% reduction

- 30 dB = 99.9% reduction

- 40 dB = 99.99% reduction

This is why small numerical differences in test reports can have massive effects in real-world blocking capability.

Tips for Consumers Buying Frequency Blocking Materials

- Look for verified attenuation data (in dB + frequency range).

- Favor products with independent lab testing — especially ASTM D4935 or IEEE 299 references.

- Match material to your target frequency: e.g., silver fabrics for Wi-Fi/5G, mu-metal for low-frequency magnetic.

- Mind installation: paints and foils require grounding; fabrics need full coverage.

- Avoid pseudoscience: if it doesn’t list measurable data, it’s not a true frequency blocker.

Conclusion

The effectiveness of frequency blocking materials is measurable, quantifiable, and rooted in real physics — not marketing hype. By understanding the basic metrics (like dB attenuation) and recognizing credible testing standards, you can separate scientifically tested products from questionable ones.

The takeaway:

- Frequency blocking materials work when properly selected and installed.

- Their performance depends on frequency, material composition, and testing method.

- Always prioritize verified data over claims.

Armed with this knowledge, you can confidently choose paints, fabrics, or foils that genuinely reduce unwanted exposure and interference — helping you create a healthier, quieter, and more controlled wireless environment.

References

- IEEE 299-2006 Standard for Measuring Shielding Effectiveness

- ASTM D4935-18 Standard Test Method for Shielding Effectiveness

- NIST EMF Metrology Program

- LBA Group – RF Shielding Products and Data

- DefenderShield EMF Fabric Specifications

- WOREMOR RF Paint Technical Data Sheet

- Electronics Notes: Shielding Effectiveness Explained

Featured Products

Looking for quality EMF protection? Check out these recommended products: