The Finishing Seal for EMF-Protected Spaces

When constructing or retrofitting an RF or EMF shielded environment, even the smallest openings—screw holes, seams, or cable penetrations—can weaken performance. RF shielding caulk is a specialized conductive sealant designed to close those gaps, preserving the continuity and effectiveness of your shielding barrier.

Used in conjunction with shielding paint, foil, or conductive fabrics, this caulk ensures that your RF protection system remains seamless, grounded, and long-lasting.

What Is RF Shielding Caulk?

RF shielding caulk (sometimes called conductive sealant) is a flexible, conductive compound formulated with metallic or carbon-based fillers that block radiofrequency (RF) and electromagnetic interference (EMI).

Unlike standard caulks, which only provide an air or moisture seal, shielding caulk establishes electrical continuity between adjacent conductive materials—ensuring that no EMF can “leak” through cracks or seams.

It’s the final layer of defense in RF-protected walls, ceilings, windows, and enclosures, particularly at points where two surfaces or materials meet.

How RF Shielding Caulk Works

The principle is simple but crucial. RF shielding caulk contains conductive particles (such as copper, nickel, aluminum, or carbon) suspended in a flexible binder. Once cured, these particles form an electrically conductive network that allows the seal to reflect or absorb EMF and RF energy rather than allowing it to pass through.

When used to fill joints or seams between conductive layers—like shielding paint, foil, or mesh—it maintains electrical continuity, which is vital for a true Faraday-cage effect.

Mechanisms of Protection:

- Reflection: Metallic fillers reflect electromagnetic waves away from the surface.

- Absorption: Part of the wave energy is absorbed by the conductive matrix.

- Conductivity: The cured caulk ensures all parts of the barrier are electrically connected.

Proper application and grounding integration ensure optimal attenuation across the protected structure.

Key Material Types and Properties

| Material Type | Primary Filler | Conductivity | Shielding Effectiveness | Flexibility |

|---|---|---|---|---|

| Nickel-Graphite Caulk | Nickel-coated graphite | Excellent | 50–70 dB | High |

| Silver-Coated Copper Caulk | Silver and copper blend | Exceptional | 70–90 dB | Moderate |

| Carbon-Loaded Caulk | Carbon and graphite | Moderate | 40–60 dB | High |

| Aluminum-Based Caulk | Aluminum powder | Good | 45–65 dB | Medium |

Most residential and commercial EMF mitigation projects use nickel-graphite or carbon-loaded caulks for performance, affordability, and safety.

Common Uses of RF Shielding Caulk

1. Sealing Gaps and Seams

Used to fill joints between:

- RF shielding paint layers

- Overlaps in RF shielding foil or metal mesh

- Gaps between conductive window frames or doors

2. Cable and Conduit Penetrations

Prevents EMF leakage where power lines, Ethernet cables, or pipes pass through shielded walls.

3. Perimeter Grounding Joints

Applied around grounding plates, bonding straps, and electrical connection points to maintain consistent conductivity.

4. SCIF and Secure Room Applications

In government or military facilities, conductive caulk is used to meet TEMPEST and NSTISSAM Level I–III standards for information security shielding.

5. Repairs and Maintenance

Used for re-sealing or patching minor cracks or seams in existing shielding systems.

Installation Process

1. Surface Preparation

- Clean the area of dust, oils, and old paint or sealant.

- Ensure both surfaces being joined are conductive or treated with shielding paint.

2. Application

- Apply using a standard caulking gun.

- Smooth with a plastic tool or gloved finger to ensure even contact.

- For grounding continuity, overlap slightly onto the conductive surface (paint, foil, or mesh).

3. Curing

- Most shielding caulks cure within 24–48 hours at room temperature.

- Once cured, the seal remains flexible and conductive.

4. Grounding Integration

- If sealing part of a wall-to-floor connection or metal junction, verify electrical continuity with a multimeter.

- For maximum performance, integrate with grounding tape or shielding paint.

Comparison: Leading RF Shielding Caulk Products

| Brand / Product | Base Material | Conductive Filler | Shielding Range | Curing Time | Approx. Price |

|---|---|---|---|---|---|

| YShield GSX10 Caulk | Acrylic polymer | Carbon/graphite | 40–55 dB | 24 hrs | $40–$60 per tube |

| LessEMF ShieldSeal 3202 | Silicone | Nickel-graphite | 50–70 dB | 48 hrs | $55–$75 |

| 3M EC-1000 | Epoxy | Silver-copper | 70–90 dB | 24 hrs | $80–$100 |

| Safe Living Technologies RF Sealant | Polymer blend | Nickel-graphite | 55–75 dB | 36 hrs | $60–$80 |

| Chomerics Cho-Bond 1030 | Silicone | Nickel-aluminum | 60–80 dB | 24 hrs | $90–$120 |

Each of these products provides verified electrical conductivity and is compatible with RF shielding paint, foil, and mesh systems.

Performance and Testing

After installation:

- Use a continuity tester or multimeter to ensure the caulked joint conducts electricity.

- Test overall shielding using an RF meter inside and outside the shielded area.

- Look for any “hot spots” or elevated readings near seams, outlets, or conduit entries.

Well-applied RF caulk can reduce EMF leakage by up to 99.999%, especially when used alongside conductive paints and foils.

Maintenance & Longevity

- Durability: Most RF caulks maintain performance for 10+ years indoors.

- Temperature Range: Stable from -40°C to +120°C depending on formulation.

- Moisture Resistance: Silicone-based versions offer better resistance in humid environments.

- Reapplication: Check joints periodically; reapply if cracking, peeling, or discoloration occurs.

Integration With Other Shielding Products

To achieve maximum protection, RF caulk should be part of a layered shielding system, including:

- RF Shielding Paint for walls and ceilings

- RF Shielding Foil or Mesh under drywall

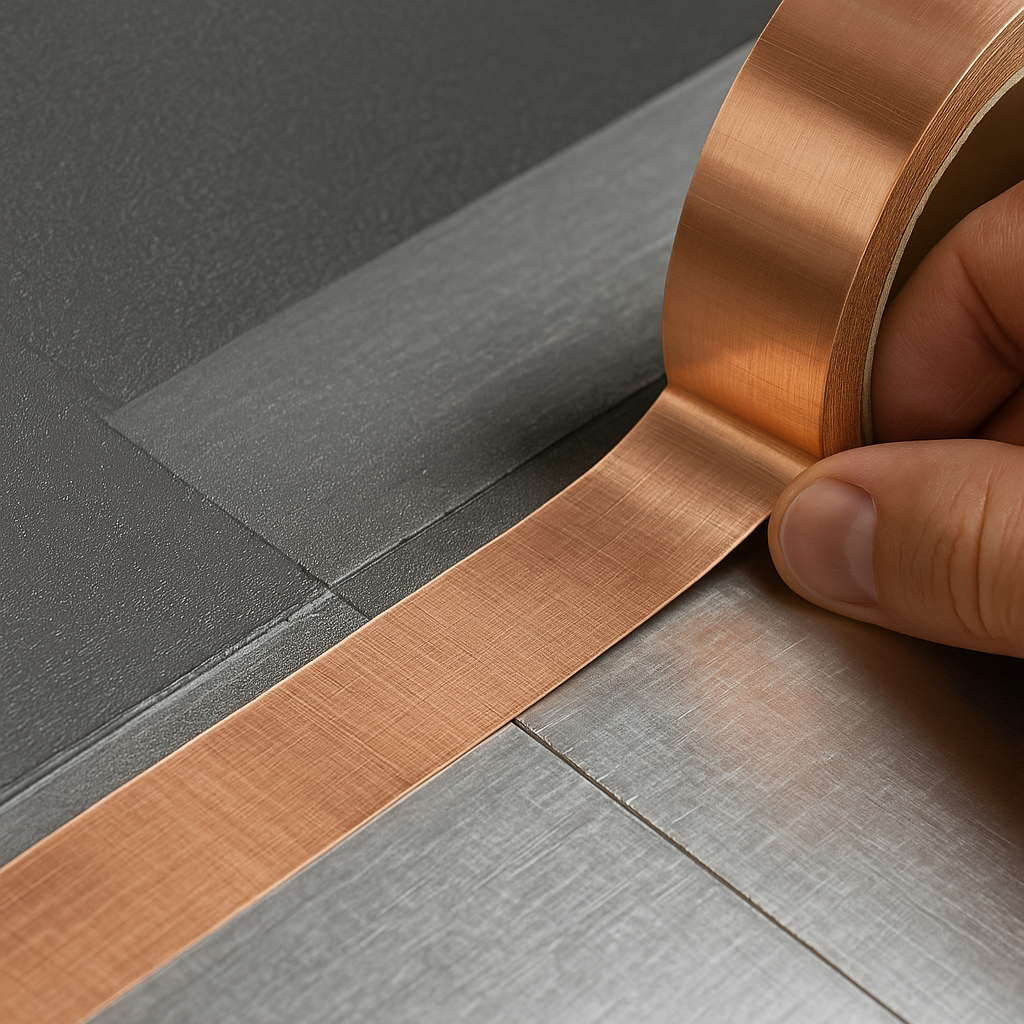

- RF Shielding Tape on seams and overlaps

- Grounding Components connecting all conductive layers

When combined, these products create a cohesive, high-performance Faraday environment suitable for both residential and commercial applications.

Safety and Environmental Considerations

Modern RF shielding caulks are:

- Low-VOC and non-toxic

- RoHS and REACH compliant

- Safe for indoor use when applied according to manufacturer instructions

Always wear gloves during application and ensure adequate ventilation until the material cures.

Key Takeaways

- RF shielding caulk fills seams, cracks, and penetrations in EMF protection systems to maintain electrical continuity.

- Typical attenuation is 40–90 dB, depending on filler material and thickness.

- Works in harmony with paint, foil, and tape to complete full Faraday shielding.

- Grounding and continuity testing are essential for peak performance.

- Ideal for both home EMF projects and professional-grade secure rooms (SCIFs).