A High-Performance Barrier Against Electromagnetic Radiation

In today’s wireless world, homes and buildings are increasingly exposed to electromagnetic fields (EMF) and radiofrequency (RF) radiation—from smart meters, Wi-Fi networks, 5G antennas, and more. While many solutions focus on fabrics, paints or films, one of the most effective and robust options is RF shielding foil: a conductive metal-foil barrier installed in walls, floors or ceilings that creates a near-complete protective layer against RF and EMF intrusion. Like RF Shielding Film, it is just one component of electrically pure spaces

What Is RF Shielding Foil?

RF shielding foil is a metallic foil or foil-composite sheet designed to block electromagnetic radiation by reflecting and absorbing RF energy. For example, the product rFOIL® (by CoverTech Fabricating Inc. / Signals Defense) is described as an “aluminum foil-based radiant barrier made up of two reflective surfaces sandwiched around a high-strength reinforcing woven scrim.”

When installed behind drywall, flooring, or in ceilings, the foil becomes a continuous conductive layer that acts much like a Faraday cage: electromagnetic waves hitting it are either reflected back or absorbed and dissipated, rather than passing into the interior space.

Key Specifications & Performance

Some key performance details for the rFOIL® product highlight the strength of foil shielding:

- The manufacturer states an attenuation of 85 dB in the 100 MHz to GHz range. Signals Defense

- The material reflects up to 97% of radiant heat (infrared) and adds thermal insulation advantages. Signals Defense

- Available roll size: 48″ × 125′ (500 sq ft per roll) for certain builds. Signals Defense

- Meets stringent standards such as those required for SCIFs (Sensitive Compartmented Information Facilities) and TEMPEST-level eavesdropping protection. Signals Defense

In practical terms, an 85 dB reduction means the RF signal penetrating through is reduced by more than 1/300,000 of its original power (since each 10 dB is a tenfold reduction). That level of shielding is markedly higher than most fabrics or paints.

How It Works: The Science Behind The Shield

When RF waves strike the conductive foil layer, several things happen:

- Reflection: The foil’s metallic surface causes the wave to bounce back toward its source rather than entering the space.

- Absorption / Dissipation: Some energy is converted into small amounts of heat or dissipated along the conductive path (especially when grounded).

- Grounding and Enclosure Effect: When the foil is properly grounded and fully enclosed (i.e., overlaps + sealed edges), it forms a contiguous conductive “shell” that prevents radiation from finding an entry path.

Because the foil is embedded in or behind structural surfaces (walls/floor/ceiling), it provides a stable and permanent layer—unlike fabrics or films that may shift or degrade.

Materials & Build-Up

RF shielding foils are composed of:

- Reflective metal layers: Usually aluminum or other conductive metal.

- Woven scrim/screen reinforcement: Adds strength, tear resistance, dimensional stability.

- Adhesive or bonding layers: If designed for retrofit use.

- Optional perforation: Some installations allow perforated foil for ventilation or architectural integration. Signals Defense

Because the foil is extremely conductive and forms a continuous layer, it’s relatively thickness-insensitive—the key attributes are continuity, overlap of seams, and connection to ground (if needed).

Benefits of RF Shielding Foil

- Exceptional attenuation: With high-dB ratings (for example 85 dB), foil provides far greater shielding than many textiles or films.

- Durability: Embedded behind walls/ceilings, foil is more protected from wear, abrasion, sun-exposure, and aesthetic changes.

- Multi-functionality: In the case of rFOIL®, it also reflects radiant heat, boosting insulation performance. Signals Defense

- Suitable for professional/commercial spec work: Meets SCIF and TEMPEST criteria, making it suitable for critical installations.

- Seamless integration: Once behind drywall or finish surfaces, the foil layer is invisible to occupants.

Installation Considerations & Best Practices

To maximize performance of RF shielding foil, you should pay attention to:

Coverage and Continuity

- Foil must span the entire area needing shielding (wall, ceiling, floor) with overlaps at seams.

- Gaps and un-sealed edges significantly reduce effectiveness—RF will “leak” through openings.

- Stagger joints, cover corners, and extend into adjacent surfaces if possible.

Grounding (If Applicable)

- While the primary shielding effect is reflection/absorption, grounding the conductive layer improves electric field mitigation (not just RF).

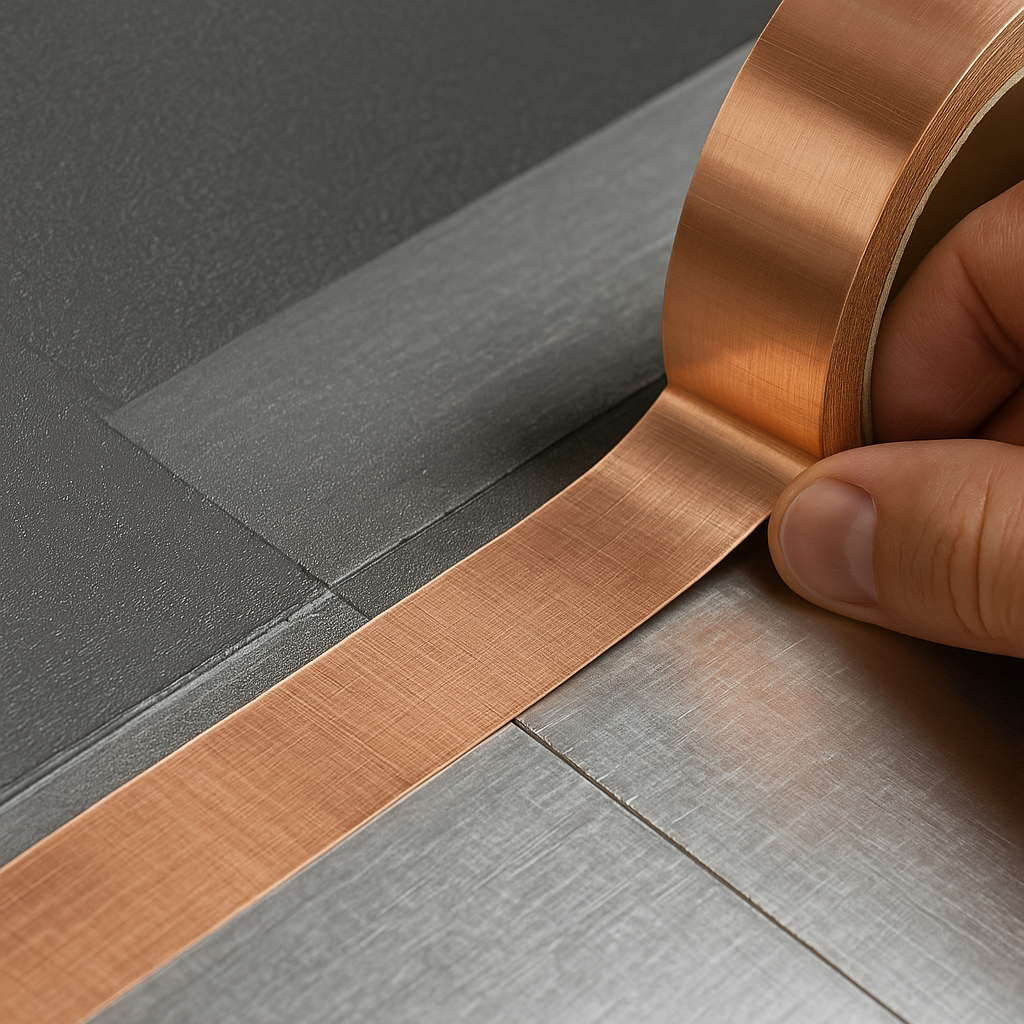

- Connect a grounding braid or tape from the foil layer to a verified earth-ground or equipment ground.

Layering with Other Materials

- Foil works best when paired with other shielding layers: e.g., a shielding paint inside, or shielding film on windows, to create holistic protection.

- The manufacturer of rFOIL® recommends using it “alongside RF paint or radiant barrier paint.” Signals Defense

Moisture and Thermal Considerations

- Because foil is metal-based, it must be protected from corrosion (e.g., in humid or wet applications).

- Thermal bridge risk may arise—ensure appropriate insulation is retained.

- In some installations, foil also serves as a radiant heat barrier (as noted for rFOIL®).

Testing and Verification

- As with any shielding system, measure baseline RF or EMF levels before installation.

- After install, re-measure across the same points to verify actual dB reduction.

- Use instruments capable of measuring the relevant frequency bands (100 MHz to multiple GHz).

Comparison: RF Shielding Foil vs. Other Shielding Options

| Option | Typical Attenuation | Visibility / Aesthetic Impact | Best Use Case |

|---|---|---|---|

| Shielding Fabric | 20–60 dB | Visible textile, drapes or panels | Bedrooms, furniture, portable setups |

| Shielding Paint | 30–70 dB (depends on coats) | Requires painting finish | Retrofitting walls/rooms with finish surface |

| Shielding Film (Windows) | 25–60 dB | Transparent or tinted film on glass | Glass-heavy rooms, preserving view/light |

| Shielding Foil | 70–90 dB+ | Hidden behind surfaces | Full-room or building shell installations |

Hence, foil is often the best choice when you’re installing shielding at the structural level, want highest performance, and are okay with the work being behind finished surfaces.

Ideal Applications

- Homes or apartments in very high EMF or RF environments (near cell towers, radio transmitters).

- Bedrooms where sleep quality is critical and other sources of EMF intrusion come through walls/ceilings.

- Offices or studios where sensitive electronics must be shielded from stray RF.

- Special-purpose rooms such as recording studios, labs, or secure facilities (SCIFs).

- New builds or major remodels where integrating foil under drywall is feasible.

Common Mistakes and How to Avoid Them

- Skipping seam overlap or edge sealing: Even one gap can compromise the shielding effect.

- Ignoring grounding when electric fields matter: Without grounding, you may still have RF reflection but less electric-field mitigation.

- Combining incompatible materials: Some low-E glass coatings, conductive paints, or films may interact poorly unless specified.

- Expecting “zero exposure”: Even with high-quality foil, other sources (wiring, devices inside the room) will still exist—foil is one layer of a system.

- Poor verification: Installing shielding and assuming results is risky—always test before and after.

Key Takeaways

- RF shielding foil is one of the most effective structural solutions for reducing EMF and RF intrusion, with attenuation ratings often above 70–80 dB.

- It functions by reflection and absorption of electromagnetic waves and can also deliver heat/radiant protection in some products.

- Proper installation—coverage, seam sealing, grounding—is essential for real-world performance.

- Use foil when you need the highest level of protection and you’re able to integrate it into walls, ceilings or floors.

- For a more complete low-EMF environment, combine foil with films, fabrics and paints to address all penetration paths.