Nickel Coated Paint: A Complete Guide for RF and EMF Frequency Blocking (2026 Edition)

Nickel coated paint is one of the most advanced and effective shielding materials for blocking high-frequency electromagnetic radiation, including 5G, WiFi, Bluetooth, RFID, smart meters, and cellular signals. As secure communication, digital privacy, and electromagnetic health become increasingly important, nickel coated paint has emerged as a professional-grade solution for creating shielded rooms, EMF-protected spaces, and RF-controlled environments.

This comprehensive guide explains how nickel coated paint works, when to use it, how it compares to carbon-based paint, which brands manufacture it, and how to install it properly. Whether you’re designing a privacy room, a Faraday-style office, a research lab, or a secure communications environment, nickel coated paint may be the most reliable tool available.

What Is Nickel Coated Paint?

Nickel coated paint is a conductive EMF-shielding coating formulated with finely milled nickel particles suspended in a binder. When applied to walls, ceilings, or enclosures, it creates a continuous metallic surface that significantly attenuates radiofrequency waves.

Unlike general wall paint, this provides:

- High conductivity

- Broad-spectrum RF attenuation

- Strong reflectivity to wireless signals

- Compatibility with grounding systems

- Stability across a wide frequency range

Nickel is one of the most effective materials for RF shielding due to its high magnetic permeability and conductivity. This makes it effective not only for high-frequency RF, but also for low-frequency magnetic fields in certain applications.

How Nickel Coated Paint Works

The shielding effect occurs through reflection, absorption, and conductive dissipation.

1. Reflection of RF Energy

Nickel coated paint reflects incoming RF waves due to the metallic surface. This prevents WiFi, 5G, Bluetooth, and cellular signals from penetrating through the treated structure.

2. Absorption at Specific Ranges

While reflection is the primary mechanism, nickel coated paint also absorbs certain frequencies, reducing electromagnetic noise and interference.

3. Conductive Barrier

Once grounded, the paint forms a conductive shield that reroutes RF energy to ground. This protects sensitive equipment, secure communications, and privacy environments.

These combined mechanisms make nickel coated paint a high-performance alternative for environments requiring measurable, testable RF reduction.

Performance Characteristics of Nickel Coated Paint

Nickel coated paint is typically used in professional installations because of its measurable attenuation values and reliable stability.

Most industrial-grade products provide:

- 40–100 dB attenuation depending on frequency

- High conductivity (0.1–20 ohms/sq depending on formulation)

- Strong shielding in the GHz range

- Coverage of 75–120 sq ft per liter

- Compatibility with grounding plates

- Water-based formulas for safe indoor use

Its performance is especially notable for high-frequency signals such as 5G and WiFi 6, which can penetrate homes more easily than older technologies.

Best Use Cases for Nickel Coated Paint

This paint is typically used where maximum RF reduction or digital privacy is required.

Top applications include:

Corporate Security Rooms

Used to protect company data, confidential meetings, and sensitive equipment.

SCIF-style environments

Nickel coated paint is often part of multi-layer shielding systems for defense, law enforcement, or high-security applications.

Laboratories and Research Facilities

Helps prevent RF interference during experiments and measurements.

Medical Environments

Can reduce interference around diagnostic equipment.

Residential Shielded Rooms

Homeowners use coated paint to block intrusive neighbor WiFi, smart meter radiation, or nearby cell tower signals.

RF-Controlled Production Facilities

Used in environments where wireless activity must be minimized.

Nickel coated paint is often selected when carbon-based paint is not sufficient, or when reflectivity is required instead of absorption.

Nickel Coated Paint vs. Carbon-Based Paint

While both are used for RF shielding, their performance characteristics differ significantly.

Nickel Coated Paint

- Higher attenuation, especially at high frequencies

- Reflective shielding

- More conductive

- Best for security and technical applications

- Requires precise grounding

Carbon-Based Paint

- Absorptive shielding (not reflective)

- Lower but more stable attenuation across wide ranges

- Easier for residential installation

- Less conductive, but simpler grounding requirements

Which should you choose?

Use nickel coated paint for:

- Maximum RF reduction

- High-security rooms

- Labs or corporate spaces

- 5G and GHz-range attenuation

Use carbon-based paint for:

- Bedrooms and homes

- Low-EMF spaces

- Affordable DIY installations

Many large projects combine both layers for hybrid reflective + absorptive shielding.

How to Install Nickel Coated Paint

Installation follows a step-by-step procedure similar to carbon paints but with more emphasis on grounding.

1. Surface Preparation

- Remove dust, oils, and debris

- Drywall, plaster, concrete, brick, and cement all qualify

- Repair cracks and holes

2. Apply a Primer

Most manufacturers require a high-bond primer before applying nickel coated paint.

3. Apply the Nickel Coated Paint

- Apply with roller or HVLP sprayer

- Use two coats for full attenuation

- Maintain consistent thickness

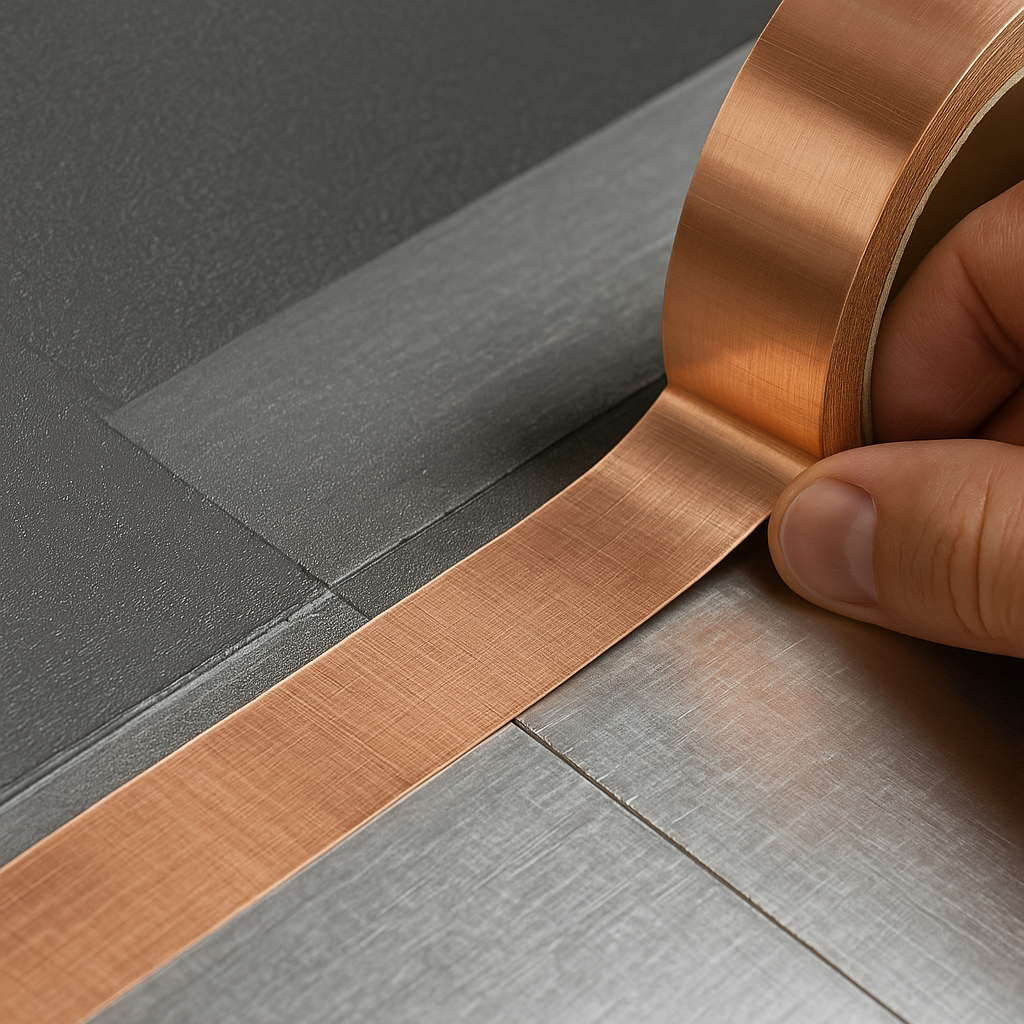

4. Ground the Shielding Layer

This is essential for reflective shielding performance.

Ground using:

- Ground plates

- Copper tape

- Manufacturer-approved ground connectors

5. Apply a Topcoat

Any standard latex or acrylic paint can be used as a finishing layer.

Common installation errors

- Using only one coat

- Forgetting grounding

- Applying too thinly

- Mixing with standard paint (never mix)

Proper installation is essential for ensuring the expected dB attenuation values.

Top Brands Offering Nickel Coated Paint (2026 Overview)

While carbon-based shielding paints are more common, several industry-leading manufacturers produce high-quality nickel coated paint.

Below is a brand-by-brand breakdown.

1. Faraday Structures – EMCoat Nickel Series

(Included in your EMF Industry Product Specs Library)

Faraday Structures manufactures some of the most advanced industrial-grade shielding paints, including nickel-filled formulations.

Features:

- High-density nickel content

- Engineered for walls, ceilings, and enclosures

- Compatible with their grounding plates, EMShield Wallpaper, and EMCaulk

- Extremely consistent RF performance

Best for:

- Corporate secure rooms

- Defense and law enforcement use

- High-interference technical environments

The company provides full spec sheets, making their nickel coated paint ideal for professional contractors and engineers.

2. YShield – NF Series Nickel Shielding Paint

YShield produces a nickel-based shielding paint known internationally for high attenuation and excellent performance.

Features:

- Up to 80–100 dB attenuation

- Very low odor, water-based

- Fine nickel particle dispersion

- Compatible with standard topcoats

Best for:

- GHz-level shielding

- Communications rooms

- RF-sensitive installation

YShield is widely used in Europe and North America by professional installers.

3. Safe Living Technologies – Nickel Shielding Coating

Safe Living Technologies distributes nickel-coated shielding systems for both residential and technical use.

Features:

- Conductive nickel-based formula

- Reliable performance across high frequencies

- Designed for compatibility with SLT meters and grounding components

Best for:

- Technical rooms

- High-security workspaces

- Lab environments

SLT remains a trusted name in EMF testing and shielding solutions.

4. Custom and Industrial Nickel Shielding Coatings

Several industrial manufacturers produce nickel coating systems for electromagnetic compatibility (EMC) applications.

These coatings are used in:

- Aerospace

- Automotive EMI reduction

- Electronic enclosures

- RF-sealed chambers

- Manufacturing plants

While not consumer-facing, these products are often the highest performing shielding paints available.

How to Choose the Right Nickel Coated Paint

The ideal choice depends on your goals, location, electrical grounding options, and the type of RF exposure you’re trying to control.

Factors to consider:

1. Target attenuation

For high security, choose 80–100 dB products.

For residential use, 40–60 dB may be sufficient.

2. Surface material

Different brands perform better on:

- Concrete

- Drywall

- Plaster

- Masonry

3. Installation environment

Some nickel coated paints require professional application.

4. Budget

Nickel formulas generally cost more than carbon paints.

Expect $200–$850 per room depending on size.

5. Compatibility with other shielding layers

Nickel paints integrate well with:

- EMF wallpaper

- Shielding mesh

- RF window film

- Grounding plates

- Shielding caulk

Building a Fully Shielded Room Using Nickel Coated Paint

A full RF-controlled environment typically includes:

- Two coats of nickel coated paint

- Grounding plates connected to electrical ground

- RF window film on all glass

- Shielding caulk around electrical boxes

- Optional carbon layer for absorption

- Topcoat finish

This combination is commonly used in:

- Secure meeting rooms

- Executive privacy suites

- Server rooms

- Medical diagnostic areas

- Government facilities

When sealed properly, the room can significantly reduce RF penetration from all directions.

Internal Resource for Readers

Learn more about shielding options and RF privacy solutions in our Faraday bags guide:

https://frequencyblockers.com/best-faraday-bags-2026/

Key Takeaways

- Nickel coated paint is one of the strongest RF and EMF shielding materials available.

- It works through reflection, absorption, and conductive dissipation.

- Typical attenuation ranges from 40 to 100 dB.

- Proper installation requires two coats and grounding.

- Leading brands include Faraday Structures, YShield, and Safe Living Technologies.

- Nickel coated paint is ideal for secure rooms, labs, privacy environments, and RF-controlled installations.

References

- https://www.yshield.com

- https://www.faradaystructures.com

- https://www.safelivingtechnologies.com

- https://frequencyblockers.com/best-faraday-bags-2026/

- IEEE Electromagnetic Shielding Standards

- ASTM D4935 Shielding Effectiveness Test Method

Featured Products

Looking for quality EMF protection? Check out these recommended products: